Saving your Data for the Day After Tomorrow

In 2019, a record 50 exabyte of data was delivered on tape globally. Melina Schnaudt from Fujifilm Recording Media GmbH explains why tape is standard in the field of data archiving now and will continue to be in the future.

Credit: Fujifilm Recording Media

The tape that we knew in 2000 is not in existence today – the technology we have now is just not comparable. Primarily, this is because the day-to-day use of tape has changed over time.

In the past, tape was used for back-up, and long-term data was archived on paper. Then people began to use hard disks for back-up, whilst paper archives started to be replaced due to the increasing regulations for the long-term retention of data alongside the digitalization of data. This marked the beginning of the age of digital archiving. At the same time that users had to ensure their data would be readable for years to come, there was a realization that hard disks were not suitable for long-term storage of data due to a lifespan of only around 3-4 years and a fragile mechanism which meant they would need to be replaced on a regular basis.

Today, tape is used across all different industries and sectors and, with a market share of 60%, it is the leading technology for data archiving.

Credit: Fujifilm Recording Media

Technology that meets ever-increasing demands

If we take all of the data stored globally (both private and professional data) on all forms of storage media including USB sticks and memory cards, we know that one seventh of all professional data is currently stored on tape. Furthermore, there is potential for growth as studies show that 24% of this is archive data and this is set to increase year-on-year. It is a figure that is never-ending due to both the anticipated future acceleration in data growth coupled with the increasing regulations on retaining data for long periods of time.

When it comes to archiving data, the nature of tape means that it is the only suitable and cost effective medium for the long-term accumulation of data.

Tape technology has been developed alongside the everyday needs of end users and the growing volumes of data that we foresee. For example, there are three groups of users who are particularly concerned with increasing capacities:

- Data Centers, Remote Sensing, Genome Research, and Social Media companies are witnessing data growth that is proportional to the growth of revenue in these industries. HSDCs, for example, are concerned with floor space reduction. The main priority is to increase the storage capacity of the tape cartridges in order to reduce the overall costs of their archive.

- The Media & Entertainment industry, hospitals, and SMEs are sectors that are not necessarily experiencing company growth, but have been confronted with a sudden increase in storage capacity requirements due to the use of new formats and applications.

- Banks, insurance companies and governments are examples of end users who request higher capacities to tackle floor space issues, in order to reduce their structural costs.

Capacity requirements are growing exponentially due to the accumulation of data and the need to reduce floor space requirements. In addition, we have found that media and scientific companies often require faster transfer rates.

The tapes of the future will meet all of these necessities.

Credit: Fujifilm Recording Media

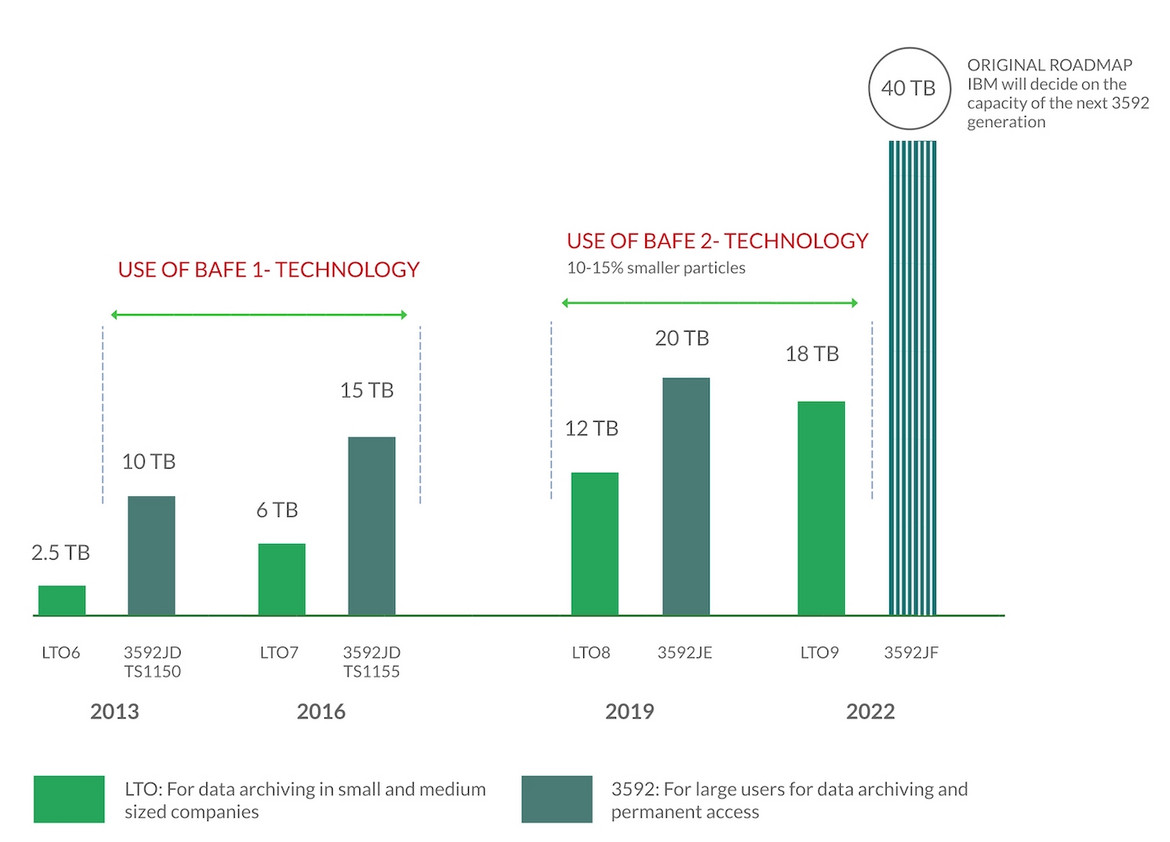

Tape is constantly evolving: LTO9 is next

There are three ways in which we can increase the capacity of a tape: by increasing the linear density, increasing the track density, and increasing the length of the tape.

The linear density is increased by increasing the number of particles that can be coated on a single writing track. The precondition is that tape’s SNR (signal-to-noise ratio) remains sufficiently high. As it was not possible to further reduce the size of metal particles, the switch to Barium Ferrite particles was made in order to increase linear density beyond 2.5 TB per tape. Furthermore, we chose to produce LTO8 using Barium Ferrite II even though it would have been possible with the first generation of Barium Ferrite.

The track is the portion of the tape on which the data is written. As the track density increases, more tracks and increased data require a head that can read and write faster and, as a result, the 32-channel head was developed. The risk associated with increasing track density is that narrowing the width of the tracks can reduce the SNR as it can make the magnetic field weaker. The IBM Terzetto head with its superior magnetic properties through three head elements provided the solution to this issue.

LTO9, which will most probably be ready in June or July, will offer a capacity of 18 TB and a transfer rate of 400 MB/s and, like LTO8, the second generation of Barium Ferrite was chosen as the coating technology. However, the linear density only needed to increase by 4% – instead, manufacturers decided to increase the track density. This shows that we are just at the beginning of the future potential in the area of linear density for upcoming generations and, most importantly, we are just at the beginning of the potential with Barium Ferrite II. In fact, when you look at the roadmap provided by the LTO consortium, capacities up to and including LTO12 can probably still be produced with Barium Ferrite II. Barium Ferrite already proved its ability to coat a single tape with a native capacity of 220 TB in 2015.

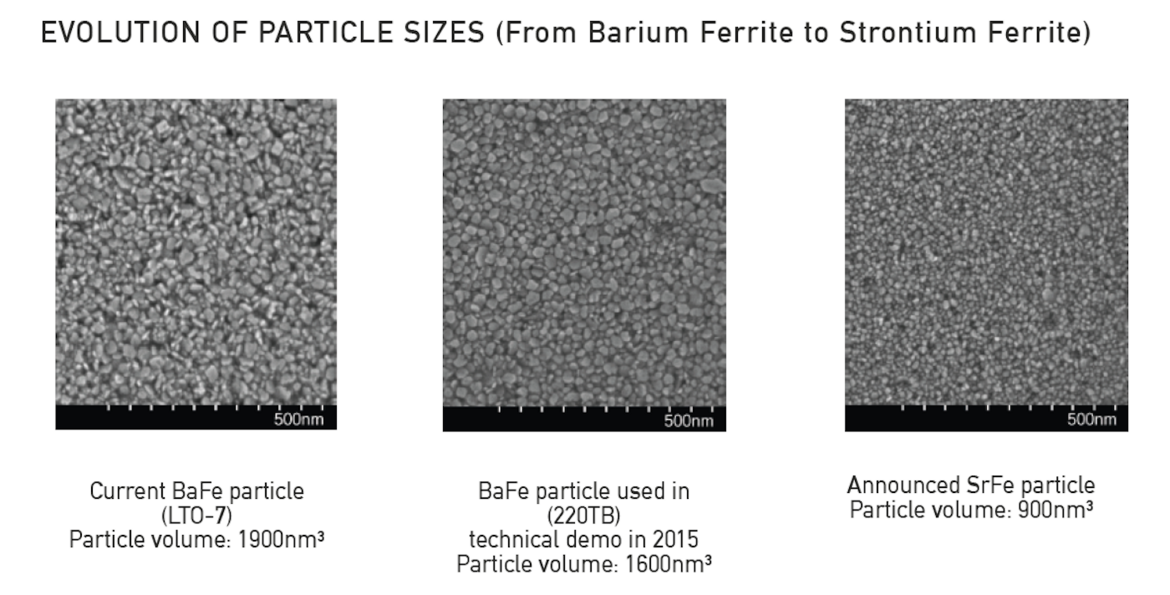

Furthermore, for the more distant future, like the 2030s, we already know which coating material will be used for producing LTO tapes: Strontium Ferrite. The magnetic properties of Strontium Ferrite are so much greater that we can reach the same performance as Barium Ferrite, but with a particle that is 40% smaller (illustrated in the image below).

Fujifilm and IBM recently set a world record using Strontium Ferrite by demonstrating that it is possible to produce tapes with a capacity of 580 TB per cartridge.

Credit: Fujifilm Recording Media

Melina Schnaudt coordinates EMEA-wide communication about the developments in tape technology at the Kleve office at Fujifilm Recording Media. With her MBA in Marketing Management and her editorial background in the technical press, she covers all fields of communication, including the website, press, exhibitions, and advertising material. At the moment, she is developing content on new fields of tape technology, such as, for example, the ecological footprint of tape and the future challenges for data archiving.

Please note: The opinions expressed in Industry Insights published by dotmagazine are the author’s own and do not reflect the view of the publisher, eco – Association of the Internet Industry.